Press Forming / Precision Stamping

Sheet forging is unique technology developed from experience of pressing & forming. Secondary operations such as machining, annealing and bonderizing. can be omitted. Overall mass weight can be reduced. Our forming / stamping processes achieve multiple thicknesses and complicated shapes and attain near net shape.

Hub Forward Clutch

Hub CVT

Hybrid Break Pump Pressure Vessel

Oil Pump Sprocket

Seat Adjuster Gear

Processes

- Metal Sheet Forging

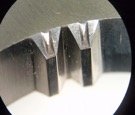

- Teeth Shape Forming

- Cold Forging Transfer

- Precise Shearing

- Metal Flow Control

Applications

- Transmission

- Suspension

- Power Steering

- Engine Systems

- Brake Systems

Equipment

Cold Forging Transfer Press

- 1,600 ~ 12,000kN

Cold Forging Press

- 2,200 ~ 15,000kN

Parts Former

- 2,500 ~ 5,000kN

Automated Production Line (Press Machine)

- 450 ~ 4,000kN

Features & Benefits

- One shot teeth shape forming without rolling or transfer process

- Stamping process improves accuracy of gear / shear droop is minimized

- Improve droop and thickness reduction by combination of press and forging combination

- Mechanical properties are improved

- Weight reduction