Motorcycle rim technology continues to evolve to support weight reduction and durability to meet the requirements for rigorous motorcycle applications

Aluminum / Steel Extruded Rims

Material

- A7N01 Equivalent

- A7050 Equivalent

- A6061

- A6062

Finishes

Anodized

Paint

Features & Benefits

Widths from 1.20 to 5.00

Diameters 14 to 21

Tubed

Tubeless

Process Capabilities

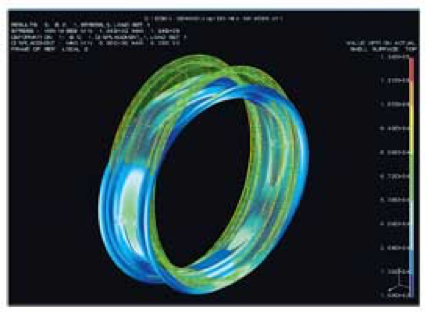

Through FEA analysis and our worldwide experience in the motorcycle industry we have succeeded in the development and mass production of light alloy rims produced to our customer’s specifications.

Motorcycle cast wheel technology continues to evolve to support weight reduction, durability and custom design to meet the requirements of rigorous motorcycle applications.

Aluminum Cast Wheels

Friction Stir Welding Technology (FSW)

Friction Stir Welding (FSW) is utilized for cast wheel production. This process allows for complex materials (dissimilar metals) to blend together becoming one single unit. FSW allows for the thermal effect of the joint to be small, minimizing deformation and maintaining mechanical properties of the base materials. Compared to MIG welding FSW eliminates pinholes, reducing porosity and air leakage. Additional advantages are increased tool life because fillers or gas sealants are not required. There is no need for pre-machining or washing process, providing a cost advantage.